- +(91)-9225101239/ 9225148586

- arunengineeringservices@gmail.com

Brazing

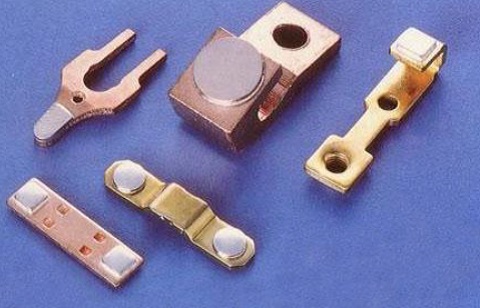

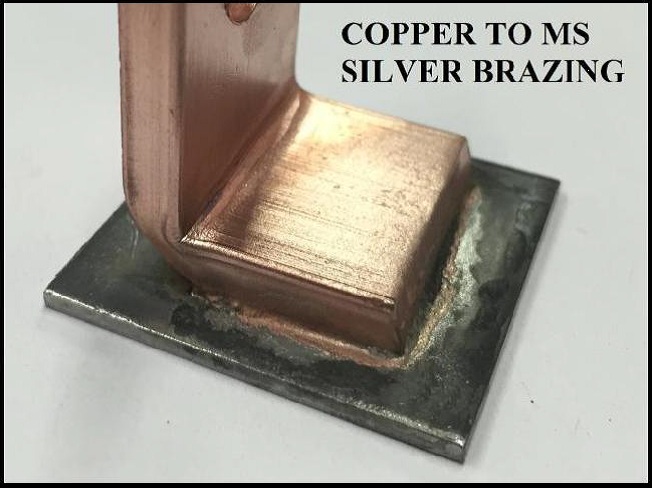

Specialized Brazing techniques and procedures are developed for low carbon and low alloy steels, copper and most copper alloys, nickel and nickel alloys, stainless steels, tungsten carbide materials. Below are the techniques that we normally choose based on clients requirements and cost structure.

Brazing or welding are preferred when strength and permanence are primary considerations. Due to the fact that in brazing a filler metal is always used and generally the entire joint area is heated at the same time, brazing is a more robust process. This means that the joint clearances, fixturing, etc are much more forgiving in brazing than in welding.

Brazing or welding are preferred when strength and permanence are primary considerations. Due to the fact that in brazing a filler metal is always used and generally the entire joint area is heated at the same time, brazing is a more robust process. Although brazing, soldering and welding are similar in many respects, there are important differences. Soldering generally can be done at lower temperatures (below 450°C), but does not produce as strong a joint. Welding, a higher-temperature process in which the two metals to be joined are actually melted and fused together, requires the most heat energy.

Brazing, which works at lower temperatures, may be the best choice for thinner parts because metal distortion can be minimized. Both brazing and welding work well for joining metals with similar melting points, but it is generally easier to join dissimilar metals with brazing. Spot joints can be easily welded or brazed, but linear joints are easier to braze because the filler metal naturally flows into the joint area.

Brazing methods in order of preference:

- Tip Brazing

- Induction Brazing

- Flame Brazing