- +(91)-9225101239/ 9225148586

- arunengineeringservices@gmail.com

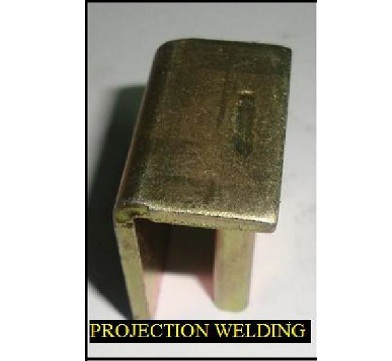

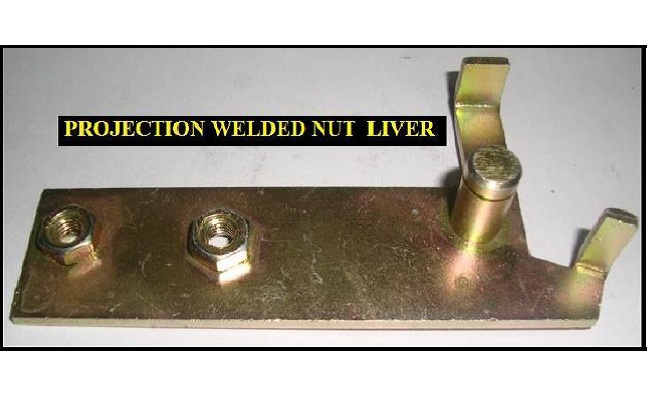

Projection Welding

Projection welding is a variation on resistance welding. Basically, a protrusion is placed on one of the two materials to be welded. Projection welding is a variation of resistance welding in which current flow is concentrated at the point of contact with a local geometric extension of one (or both) of the parts being welded. These extensions, or projections, are used to concentrate heat generation at the point of contact. Heating is facilitated by resistance heating and is highly influenced by the contact area resulting from the amount of deformation, which is also temperature dependent due to material softening therefore to generate a weld nugget faster and at a lower current level compared to conventional spot welding..The process typically uses lower currents, lower electrode forces and shorter welding times than does a similar application without the projection.