- +(91)-9225101239/ 9225148586

- arunengineeringservices@gmail.com

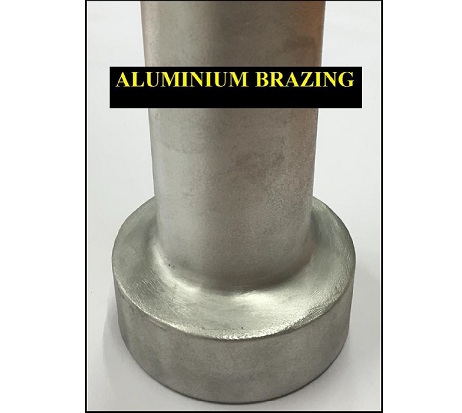

Aluminium Brazing

During welding, two metals are melted together to join them. During brazing, on the other hand, two or more materials are merged via the use of a third material. The cleanliness of parts is much more important for brazing, and because less heat is used during the process, contaminants are less likely to burn up. Brazing also allows for tighter control over tolerances.

Producing a reliably clean joint, brazing allows non-similar metals to be easily joined together. This technique is also more cost-effective, especially for complex and multipart pieces.

There are many benefits of aluminium brazing that make is a better choice than welding.

The advantages of brazing include the following:

- Low cost of entry

- Novice metalworking skill required

- Relatively safe

- Works on a variety of alloys

- Portable and convenient

- Quick repair

- Versatility

Here are some of the reasons that aluminium brazing can potentially provide a stronger joint than a weld:

Lower temperatures: The base metals in an aluminium braze are kept at a lower temperature than the base metals fused in a weld, which allows them to retain the tensile strength of the original material rather than being adversely affected by heat damage.

Less oxidation: Because aluminium can be brazed at a lower temperature than it can be welded, it is less subject to high-temperature oxidation, porosity issues, and other joint defects that can occur as the result of a high-temperature weld.

No heat distribution issues: If heat is applied unevenly to an aluminum weld, this can affect the strength of the resulting joint. Since heat is not applied to the base metal in aluminium brazing, this ambient heat issue sn’t a design challenge.