- +(91)-9225101239/ 9225148586

- arunengineeringservices@gmail.com

Induction Brazing

In addition to the general benefits induction heating brings to virtually any heating process, there are very specific reasons to use induction heating for industrial brazing. These include selective heating, better joint quality, reduced oxidation and acid cleaning, faster heating cycles and more consistent results.

Contact Heating

Induction heating can be targeted to provide heat to very small areas within tight production tolerances. Only those areas of the part within close proximity to the joint are heated; the rest of the part is not affected. Since there is no direct contact with the part, there is no opportunity for breakage. The life of the fixturing is substantially increased because problems due to repeated exposure to heat (such as distortion and metal fatigue) are eliminated. This advantage becomes particularly important with high-temperature brazing processes.

Joint Quality

Induction heating produces clean, leakproof joints by preventing the filler from flowing into areas that it shouldn’t. This ability to create clean and controllable joints is one of the reasons that induction brazing is being used extensively for high-precision, high-reliability applications.

Consistency

Induction brazing is a very repeatable process because variables such as time, temperature, alloy, fixturing, and part positioning are very controllable. By proper control over cycle time, temperature, and material handling system ‘consistency’ in maximum productivity can be achieved.

Work

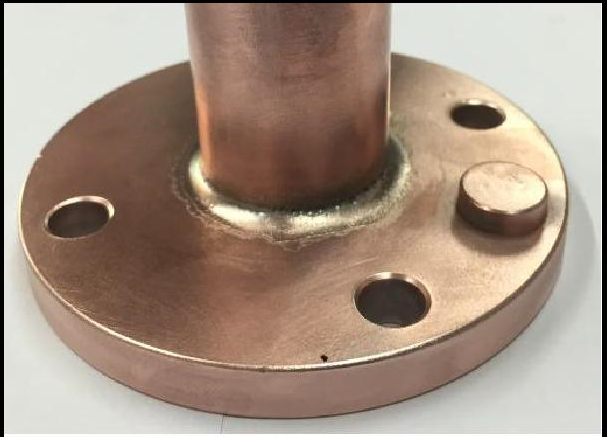

i) HV/LV Bus Bar Assemblies (any sizes)ii) Contact to braided wire Assembly

iii) Laminated Flexible Connectors

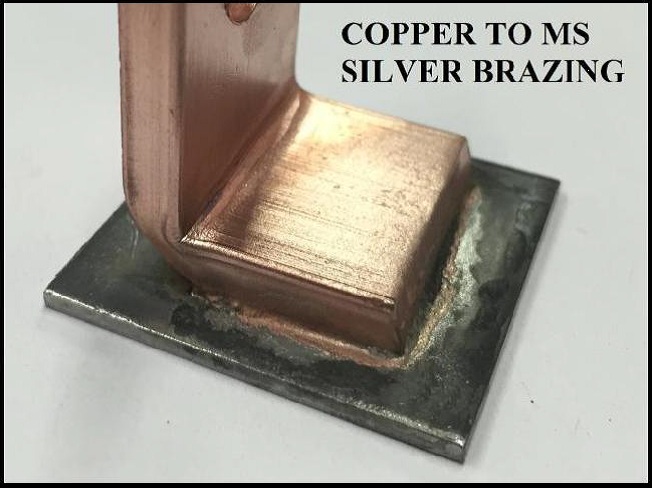

iv) Cu to Tungsten silver brazing